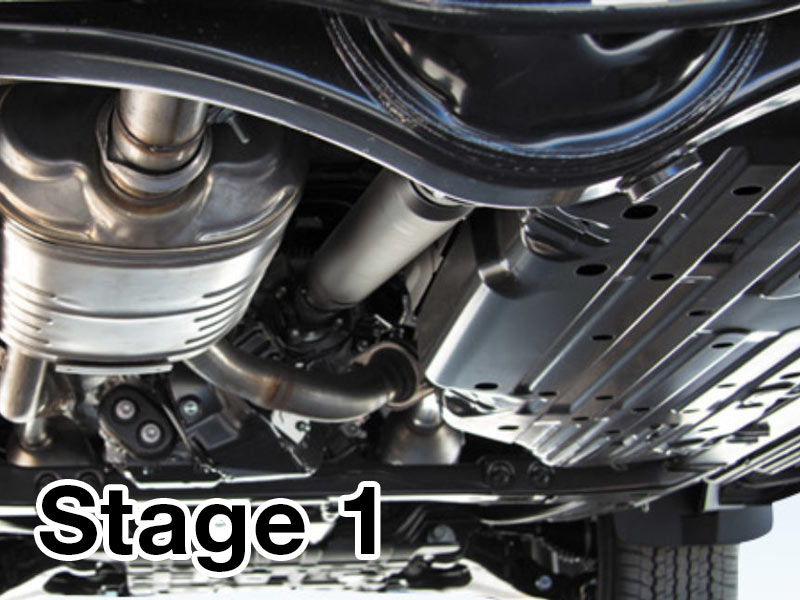

Minor Surface Contaminants, mud, small amounts of surface corrosion. All mud, salt, road film and surface rust will be removed and treated before any rustproofing can begin.

Stage 1 treatment is included with all rust prevention services. This is further detailed in our treatment guide below.

Welcome to RustProofing Wales from Rust Oust

⬤ South Wales Longest Established Rust Treatment and Protection Company

⬤ A Highly Skilled Team with Dedciated Rust Treatment Workbays

⬤ We kill the rust before we treat a vehicle.

⬤ Full Metalworking Fabrication Facilities

⬤ Sandblasting and Sodablasting available

⬤ Free Vehicle Inspection where you get to speak to the experts

⬤ Free Estimate

⬤ Visit us in Llandow Near Cowbridge, Follow Signs for Llandow Tuning

Understanding the degrees of corrosion / contaminants

Before planning a rustproofing treatment, it's important to understand the different levels of corrosion that could be evident on a vehicle. The older the vehicle, the more likely it is that there is more rust than you think. Naturally there is a price impact depending on the state of the vehicle. Below is a guide to the levels of corrosion and the preparation required.

Stage 2 surface corrosion is usually found on slightly older vehicles. Typically the underbody sealant applied by the manufacturer has started to fail. Water has got trapped underneath the failed sections. The corrosion and failed underbody sealant will need removing / preparation for treatment.

Typically we use an air needler to remove the failed underseal. Sand blasting is also an option where needed.

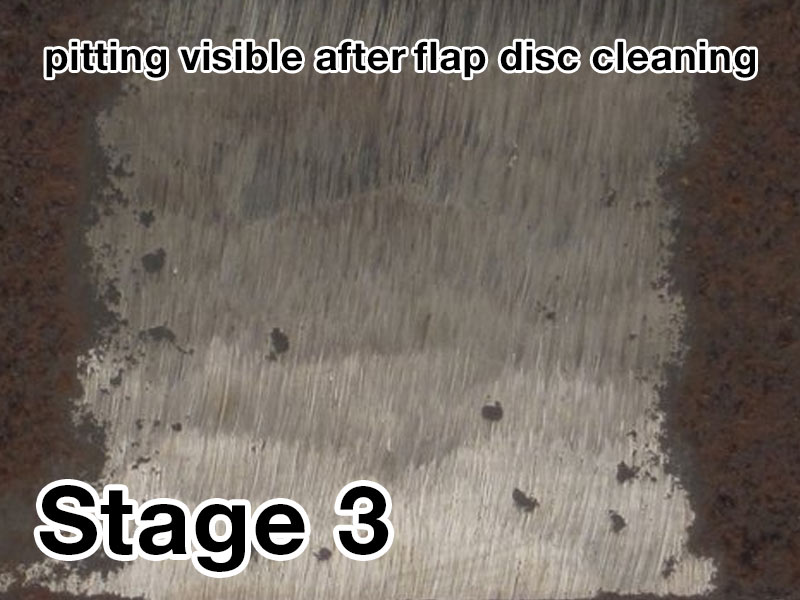

In addtion to stage 2 damage, stage 3 includes minor pitting and holes which will require all the preparation for second degree surface corrosion plus additional work to remove pitted or holed metal. Once removed welding repairs will be needed along with sealing treatments of the welded sections prior to the actual rustproofing treatment process.

Major corrosion and holes will likely have the minor pitting and holes as well as the more significant areas of damage. This will need significant welding repairs and preparation before any rustproofing treatment can be done. In some cases replacement panels or new sills may need to be sourced and installed.

The Treatment Process

A Complete Treatment, a thorough process with guaranteed results The underside of your pride and joy gets a lot of assaults from the road during driving. Surface water; grit and salt; debris all attack the underneath and cause corrosion and damage. Underbody protection is the first step in prolonging the life of your vehicle. Nearly all cars have some kind of protection from new, but there are limits to this.1. Initial Inspection

The FREE Inspection is done before we begin any rust proofing job. You can wait while we do this so we can give you a best effort estimate. Until preparation starts there is always a risk of hidden damage.

2. First Stage Cleaning

Lift vehicle, remove wheels, remove all undertrays & plastic trims to expose underside properly. Hosing of underside to remove loose dirt & grime. This DOES NOT involve a pressure washer, simply low pressure water to remove the surface contaminates

3. Second Stage Cleaning

The deeper degrease process. Application of Degreaser Agent & Salt Removal Agent to deep clean & heat applied quick drying

4. Stage 1 Initial Steam Cleaning

We steam the underside of the vehicle to remove any of the agents from step 3 and also any mud etc

5. Stage 1 Treatment

We remove any minor surface rust which might be sitting on untreated parts underneath the car. This is done by hand using a wire brush

6. Condition Assessment

Full inspection of condition & assessment of any damage or corrosion. Gentle testing of areas where corrosion is evident for any weakness of structure or hidden holes

7. Stage 2, 3 and 4 Treatments

If the vehicle requires treatment for stage 2, 3 and 4 corrosion, this is the stage we perform this.

Depending on the condition of the vehicle and the level of corrosion this can take days or even weeks. The finish and repair type is fully agreed with you before work is undertaken.

For example on a camper van you might opt to have rust holes underneath the vehicle plated, yet on a show, classic or performance car you might opt to have a factory standard finish. We could replace or repair damaged panels including cutting out affected material and replacing with new. Lead loading could also be applied to ensure a rust free repair and a greater ability of detailing in intricate areas.

8. Underside Masking

Masking of exhaust, transmission and at-risk areas for overspray. We will give you the option of whether you want us to paint the lower parts of the suspension shocks (they may be very corroded).

9. Bodywork Protection

Put on protection sheets to mask bodywork panels and prevent any overspray on vehicle paintwork

10. Rust Conversion Treatment

Application of Anti Corrosion rust converter to affected areas. I.e. areas where rust has been removed during the earlier processes

11. Priming

Where any metal has been exposed or replaced it will be painted with an anti corrosion primer.

11. Seam Sealer

Should any seam sealer have failed underneath the vehicle it will be replaced. Seam sealer will also be added around any pieces welded to the vehicle

13. Stone Chip

Application of stone chip if the sills are damaged or to inside areas (such as the floor of a van or bed of pickup). This could be in the form of Raptor or Traditional Stone chip. (Additional charges may apply)

14. Underbody Sealer

Application of underbody anti corrision sealer. This could be in the form of Dinitrol, Raptor or Schultz.

15. Hot Wax Cavity Injection

Injection of hot wax to exposed cavities using injection nozzle. Option for access holes to be made to allow cavity injection to hidden areas.

16. Cleaning and Handover Inspection

The car will be washed and the underbody protection will be inspected to ensure our standards have been met and everything is completed.

Before the vehicle is returned to you it undergoes a thorough quality control process before sign off for release by a workshop supervisor.

This includes checking the process is completed to our exacting standards, ensuring all trims have been reinstalled correctly, checking wheel bolt torque settings and of course a wash & wax so that it's all shiny to come home.

The Products

Tried, Tested, Proven Results. Guaranteed Longevity.Because we aren't linked to only one supplier we can choose the best products for each step resulting in the very best results for you and your car.

Prep Detergents.

Chlorx Salt Remover

Heavy Duty Degreaser

Rust Conversion.

Phos-Kleen B

Purple-X

FE-123

Adcoat

Flag Marine

Rust Prevention.

Dinitrol Underseal

Techshield Wax

Tetroseal Schultz

Raptor Protective Coatings

Pricing

The important matter of effect on your wallet!

Please be aware the prices shown are for all Stage 1 rust.

If your vehicle is old, or has been subject to winters with salt or has holes that need welding or repairs then

the prices will clearly differ as before the rust prevention treatment can be applied the rust first needs to be eliminated.

Natrually the 3 day timescale is for a stage 1 vehicle.

Initial Assessment

- Before we can accurately

provide an estimate we need

to see the status of the underside - Pop in during opening hours

for us to put the vehicle on the

ramp for an initial assessment - No Obligation

- Completely FREE of Charge

STANDARD

TREATMENT

Stage 1 Surface

- From £350

- Full Preparation

- Complete Treatment

- Full Cavity Protection

- 3 Day Process

- 5 Year Warranty

4x4 / Big Vehicle

Stage 1 Surface- From £450

- Full Preparation

- Complete Treatment

- Full Cavity Protection

- 3 Day Process

- 5 Year Warranty

Yearly Service

- Just £80

- Maintain your Warranty

- Rust Treatment Check

- Rust Protection Check

- Treatment of any damaged areas

(stone chips etc) - Application of Topup

Frequently Asked Questions

We've tried to answer the most common questions. If you need further assistance then please ask our staff by giving us a call.Free Assessment

Payment

Timescales

The Process

Stages

Warranty

We provide a full warranty that subject to the yearly underside servicing, that the rustproofing will last for 5 years. With the annual service we will keep your vehicles underside rust free for 5 years. Each year we can check and reapply our rust treatment (usually the cavities need topping up) to keep your vehicle free from rust for up to 5 years.After 5 years we may need to reapply the main treatment.

Why Choose Us:

When it comes to Rust Protection or Corrosion Treatments for your vehicle nobody in South Wales offers a better quality or service than Rust Oust. Keep in mind that spraying a can of waxoyl over the top of surface rust is not a rustproofing treatment. This is what most garages offer to try and mask any corrosion rather than treat it.Pricing

We keep it real with our pricing structure. No hidden costs or nasty surprises.

Experience

Years of experience mean we've perfected the process. Efficient & Effective.

Free Assessment

No obligation estimates. FREE initial assessment for accurate pricing.

Guarantees

Our rustproofing comes with a full 5 year warranty. No quibble guarantee.

Standards of Repair

Every rust prevention job we perform is always completed to a high standardWhere rust treatment is also needed at either stage 2, 3 or 4 levels we will perform the repairs needed to a standard agreed with you in advance. We can produce factory like finishes or apply patches after cutting our rust infected areas. The choice is yours.

To give you an idea of the quality and finish of our work we have created a small gallery.

Get in Touch

Call us, pop in or email, we'd love to hear from you.Request an information pack or speak to our customer sevice team today.